Description

Service background

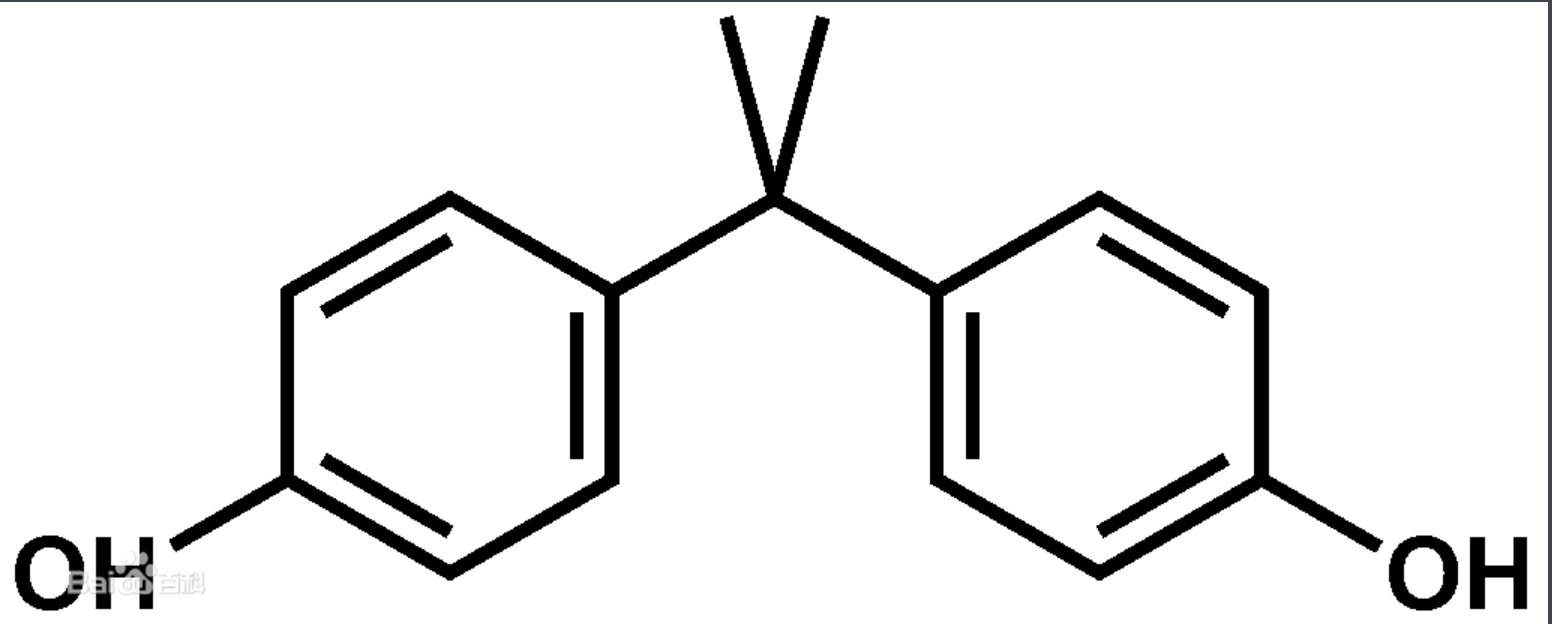

Bisphenol A, also known as BPA, is an organic compound with the formula C15H16O2

Bisphenol A is used industrially to synthesize materials such as polycarbonate (PC) and epoxy resins. Since the 1960s, it has been used to manufacture plastic (milk) bottles, suction cups for young children, and the inside coating of food and beverage (milk powder) cans. BPA is found everywhere, from mineral water bottles and medical devices to the inside of food packaging. Every year, 27 million tons of plastics containing BPA are produced worldwide. But BPA can also cause endocrine disorders that threaten the health of fetuses and children. Cancer and obesity caused by metabolic disorders are also thought to be involved. Since March 2, 2011, the European Union has banned the production of baby bottles containing the chemical bisphenol A (BPA).

Bisphenol A(BPA), a chemical commonly found in plastic bottles, may cause cancer and other disorders, according to experimental researchers in the United States. In addition, bisphenol A(BPA) can make the human hormone function disorder, the growth, development and reproduction will have potential harm, although this conclusion has not been confirmed by the authority, but some informed consumers caused consumption panic. To assist manufacturers in the compliance of their products in national markets, RTS provides professional testing services including but not limited to the following:

Service content

Scope of application

All potential products containing BPA.

2. Applicable objects

Manufacturers, brands, exporters.

3. Test requirements

China: GB 13116-91 Health standard for polycarbonate resins used in food containers and packaging materials.

GB 14942-94 Health standard for polycarbonate molding products for food containers and packaging materials.

GB/T 5009.99-2003 Method for analysis of health standards for polycarbonate resins used in food containers and packaging materials.

China’s health standards stipulate that the dissolution amount of phenol (distilled water, reflux 6h) in carbonate resin and molding products is not more than 0.05 mg/kg,

The method of titration is used to quantitatively calculate the free phenol in the solution.

Eu Regulation 2002/72/EC establishes A migration limit of 3 mg/kg for BPA/ bisphenol A in plastic food contact materials.

In the European Union, the migration amount of bisphenol A was detected by liquid chromatography (detection limit was 0.2 ~ 0.7 mg/kg).

United States: The US Food and Drug Administration (FDA) stipulates that BPA/ bisphenol A can be used as an ingredient in food contact materials.

EPA(1993) specifies that the maximum acceptable dose or reference dose is 0.05mg/kg.bw.

Japan: The Food Hygiene Law stipulates that the dissolution limit of BPA/ bisphenol A in polycarbonate food containers is 2.5 mg/kg.

Service advantage

Timeliness: RTS has a set of independently developed LIMS system, which monitors and manages the entire test process, greatly improving work efficiency and shortening the inspection cycle entrusted by enterprises.

Convenient: RTS has a perfect order platform and free on-site pick-up service, and can provide one-to-one consultation and training and one-stop product compliance service chain for enterprises.

Price: RTS in the consulting stage can be based on the product information and material situation of the enterprise comprehensive evaluation, to provide the most appropriate and the most economical quotation scheme for the enterprise, greatly reducing the test cost.

Quality: As a national high-tech enterprise, RTS has dozens of patented inventions and supporting instruments and equipment and professionals to meet the needs of different customers and different products.